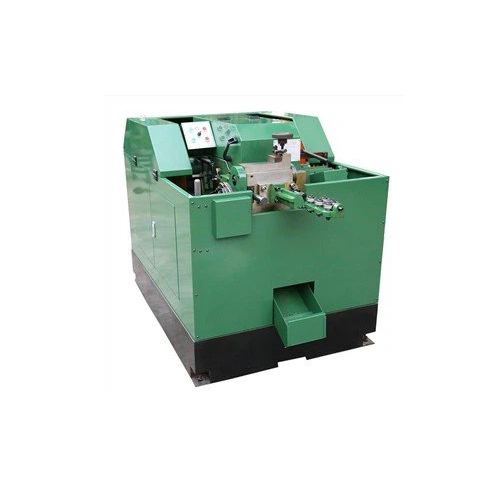

Self Drilling Screw Making Machine

Self Drilling Screw Making Machine Specification

- Product Type

- Self Drilling Screw Making Machine

- General Use

- Industrial

- Material

- Steel Alloy

- Automatic

- Yes

- Control System

- PLC Control

- Surface Treatment

- Polishing

- Feature

- High Performance, High Efficiency, Stable Operation, Simple Control

- Color

- Green

- Warranty

- 1 Years

Self Drilling Screw Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Central America, Asia, Australia, South America, Western Europe, Middle East, Africa, Eastern Europe, North America

- Main Domestic Market

- All India

About Self Drilling Screw Making Machine

Versatile Applications and Extra Features

Engineered for reliable output, this machine is suitable for manufacturing self-drilling screws used in construction, automotive, and electrical industries. Its extra features include high-capacity operation, easy PLC control, and a stable, polished build for long service life. The automatic feed system ensures minimal downtime, making it adaptable to both mass production facilities and specialized workshops. Beyond self-drilling screws, the machine accommodates a variety of screw types, maximizing its value across multiple application areas.

Flexible Payment and Delivery Solutions

With a focus on domestic markets and tailored sample policies, we ensure buyers have flexible payment terms and transparent sample options. Swift goods transport and quick dispatch guarantee timely delivery of machinery, minimizing wait times. Our efficient order management system supports streamlined purchasing, while well-structured distribution channels across key locations facilitate hassle-free transactions for both bulk and individual buyers.

Product parameters

|

Model No. |

TX-ZWJ |

|

Blank Dia.Range |

3-6mm |

|

Blank Length Range |

10-120mm |

|

Mould Size |

35*32*20mm |

|

Motor Power |

5.5kw |

|

Capacity(pcs/min.) |

250-400pcs/min |

|

Outer Size |

2170*1630*1830mm |

|

Machine weight |

2000kg |

FAQs of Self Drilling Screw Making Machine:

Q: How does the PLC control system enhance machine operation?

A: The PLC control system simplifies machine operation, offering precise, user-friendly interface that ensures consistent, stable performance with minimal manual intervention.Q: What are the main industrial applications of the Self Drilling Screw Making Machine?

A: This machine is primarily used in the production of self-drilling screws essential for construction, automotive, and electrical industries, but it can adapt to producing other screw types as well.Q: When can I expect my machine after purchase?

A: Thanks to quick dispatch protocols and reliable goods transport, orders are processed promptly. Delivery timelines depend on location and order size but are generally short within the domestic market.Q: Where is the machine manufactured and by whom?

A: The Self Drilling Screw Making Machine is manufactured in China and distributed by leading exporters, suppliers, and wholesalers with a reputation for top-notch industrial machinery.Q: What is the process to obtain a sample or inquire about sample policy?

A: Interested buyers can request sample details through our streamlined order management system. Our sample policy is straightforward and designed to help customers assess quality before finalizing a bulk order.Q: How can buyers benefit from the machines automatic and polished design?

A: With automatic feeding, polished surfaces, and high-efficiency outputs, buyers experience reduced downtime, lower maintenance, and consistently high-quality screw production, ensuring operational productivity and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Machine Category

Self Tapping Screw Making Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Years

Material : Steel Alloy

Feature : High Performance, Simple Control, High Efficiency, Stable Operation

Surface Treatment : Polishing

Color : GreenBlack

Automatic Self Tapping Screw Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Years

Material : Steel Alloy

Feature : High Performance, Simple Control, Stable Operation, High Efficiency

Surface Treatment : Polishing

Color : GreenBlack

Screw Cold Heading Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Years

Material : Steel Alloy

Feature : High Performance, High Efficiency, Stable Operation, Simple Control

Surface Treatment : Polishing

Color : GreenBlack

Drywall Screw Production Line

Minimum Order Quantity : 1 Piece

Warranty : 1 Years

Material : Steel Alloy

Feature : Simple Control, High Performance, High Efficiency, Stable Operation

Surface Treatment : Polishing

Color : GreenBlack

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free