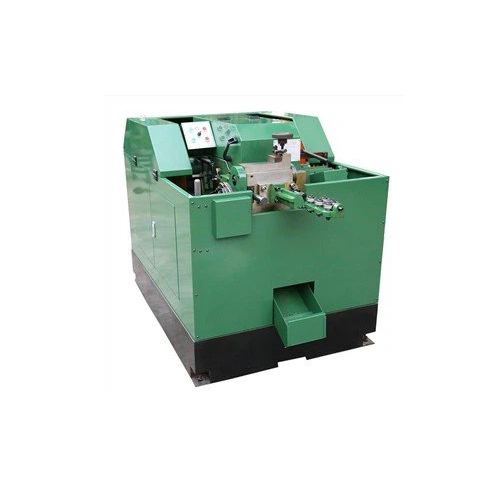

Screw Cold Heading Machine

Screw Cold Heading Machine Specification

- Product Type

- Screw Cold Heading Machine

- General Use

- Industrial

- Material

- Steel Alloy

- Automatic

- Yes

- Control System

- PLC Control

- Surface Treatment

- Polishing

- Feature

- High Performance, High Efficiency, Stable Operation, Simple Control

- Color

- Green-Black

- Warranty

- 1 Years

Screw Cold Heading Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Australia, Central America, South America, Western Europe, Middle East, Eastern Europe, Asia, North America, Africa

- Main Domestic Market

- All India

About Screw Cold Heading Machine

Screw Cold Heading Machine is a specialized machine that utilizes a cold heading process to form screw heads, shanks, and threads from raw materials such as steel, brass, and aluminum. The process involves feeding a wire or bar stock through a series of dies that shape the screw. The advanced control systems of these machines ensure precise dimensions and consistent quality, allowing for high-speed production. Screw Cold Heading Machine is widely used in various industries, including construction, automotive, and manufacturing, to produce high-quality screws that meet industry standards for strength and durability.

|

Model No. |

Blank Dia./ Length Range(mm) |

Capacity pcs./min |

Size of main Die (mm) |

Size of 1st & 2nd Punches (mm) |

Cut-off Die Size (mm) |

Outer

Size

(mm)

|

Main Motor (kw) |

Net Weight (kg) |

|

TX-10 |

2-4/5-30 |

120-170 |

30*45 |

25 |

15 |

1400*900*1100 |

1.5 |

1200 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Machine Category

Self Tapping Screw Making Machine

Minimum Order Quantity : 1 Piece

Automatic : Yes

Color : GreenBlack

Product Type : Self Tapping Screw Making Machine

Control System : PLC Control

Surface Treatment : Polishing

MDF Screw Production Machine

Minimum Order Quantity : 1 Piece

Automatic : Yes

Color : GreenBlack

Product Type : MDF Screw Production Machine

Control System : PLC Control

Surface Treatment : Polishing

Automatic Self Tapping Screw Machine

Minimum Order Quantity : 1 Piece

Automatic : Yes

Color : GreenBlack

Product Type : Automatic Self Tapping Screw Machine

Control System : PLC Control

Surface Treatment : Polishing

Gypsum Screw Making Machine

Minimum Order Quantity : 1 Piece

Automatic : Yes

Color : GreenBlack

Product Type : Gypsum Screw Making Machine

Control System : PLC Control

Surface Treatment : Polishing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry