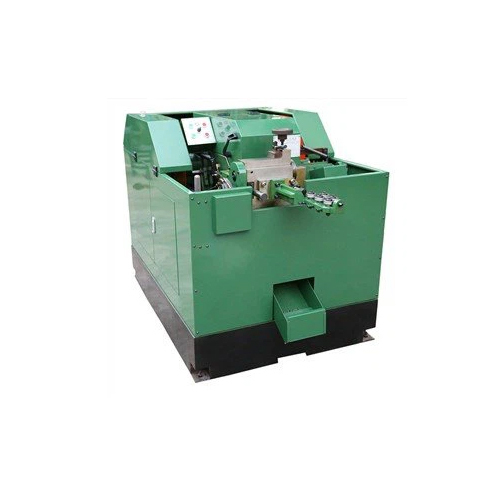

High Speed Screw Thread Rolling Machine

High Speed Screw Thread Rolling Machine Specification

- Usage & Applications

- Industrial

- Product Type

- Cast Products

- Material

- Stainless Steel

- Surface Finishing

- Polishing

- Weight

- 1800 Kilograms (kg)

- Color

- Green-Black

High Speed Screw Thread Rolling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Australia, Central America, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Africa

- Main Domestic Market

- All India

About High Speed Screw Thread Rolling Machine

High Speed Screw Thread Rolling Machine is used to create precise and accurate threads on fasteners such as bolts, screws, and studs. The machines use a cold-forming process to deform the material into the desired thread profile, rather than cutting the thread like a traditional tap or die. This method results in higher thread strength and longer thread life, as well as increased production efficiency due to faster cycle times. The machines are capable of producing threads on a variety of materials, including steel, aluminum, brass, and titanium, and can create threads in a range of sizes and pitches. High Speed Screw Thread Rolling Machine are commonly used in the automotive, aerospace, and construction industries.

Product Type - High Speed Screw Thread Rolling Machine

Automation Grade - Automatic

Usage - Industrial

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Forging Machine Category

Screw Bolt Re Header Making Machine

Minimum Order Quantity : 1 Set

Weight : 1800 Kilograms (kg)

Color : GreenBlack

Material : Iron

Surface Finishing : Polishing

Usage & Applications : Industrial

Automatic 1-Die 2-Blow Screw Making Machine

Minimum Order Quantity : 1 Piece

Weight : 1300 Kilograms (kg)

Color : GreenBlack

Material : Stainless Steel

Surface Finishing : Polishing

Usage & Applications : Industrial

Automatic Opening Die Cold Forging Machine

Minimum Order Quantity : 1 Piece

Weight : 3500 Kilograms (kg)

Color : GreenBlack

Material : Iron

Surface Finishing : Polishing

Usage & Applications : Industrial

Advanced Screw Manufacturing Cold Heading Machine

Minimum Order Quantity : 1 Piece

Weight : 1850 Kilograms (kg)

Color : GreenBlack

Material : Stainless Steel

Surface Finishing : Polishing

Usage & Applications : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry